340k Hydraulic

Work Over Unit

Our Approach:

- Excellence…Performance…Safety

340k Hydraulic

Work Over Unit

- Safer and more Efficient than any other HWU currently on the market.

- The only API Certified Hydraulic Work over Unit of its kind, in the WORLD

-

Rated for:

130MPH Wind Loading

6.0 Seismic loading - Does carry the API Monogram Placards

- Built to API 4-F and 8-A Specifications

Overview

- 340K Jack

- 15’ stroke vs 10’ stroke

- Cycle Time/Trip Time Efficiency: Increased by 33%

- 2 strokes to get a standard joint out of the hole instead of 3 strokes.

HPU

- CAT C-15 Zone Rated Class 1, Div. 2, Tier 3 Engine (greenest on market for offshore applications)

Work Platforms

- 4 pieces: 2 sides, mid, work

- Fully Enclosed= safer working area; no need for harness and vertical climbing

- Guide and Pin= No more nuts/bolts

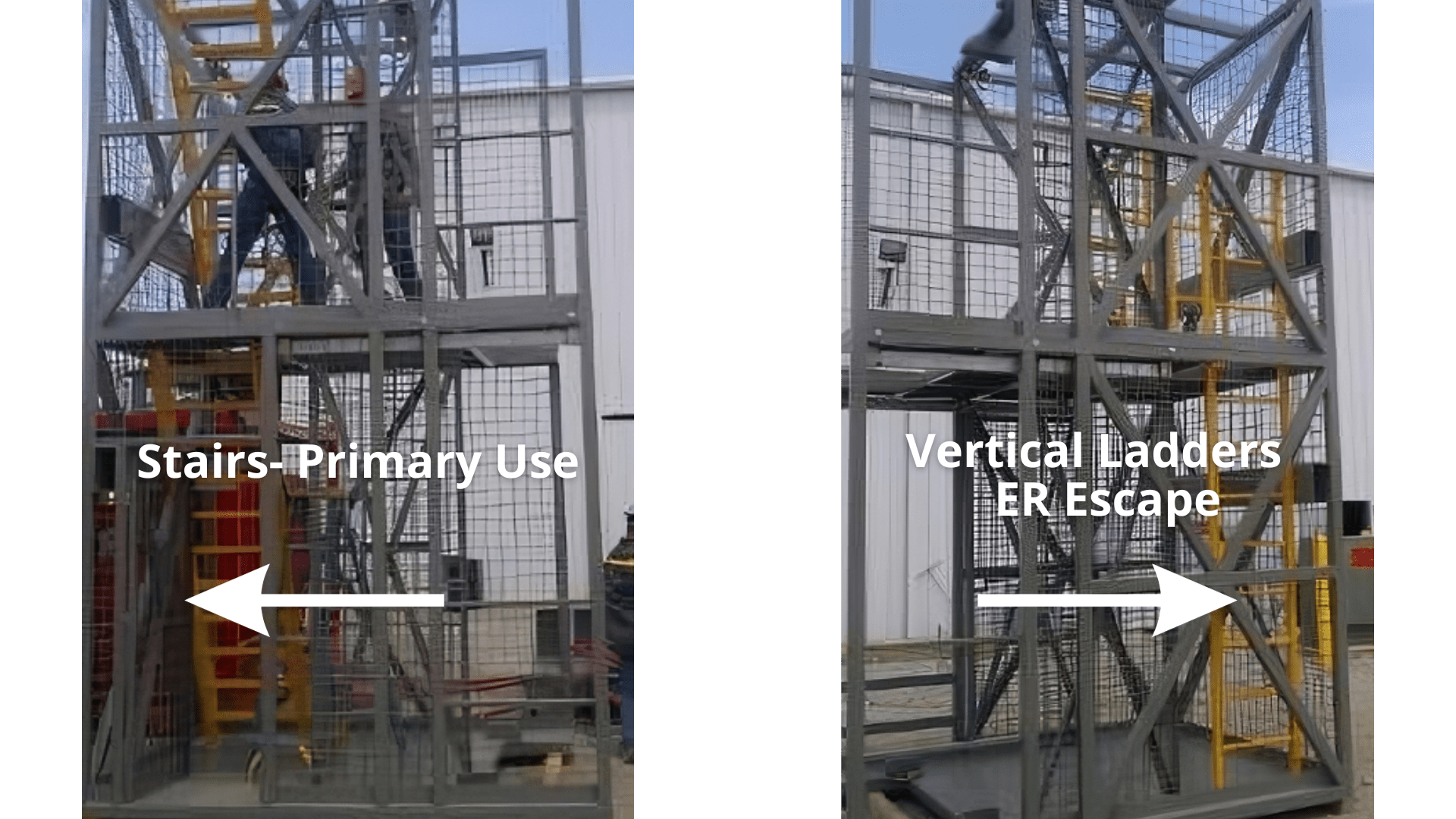

- Internal Stairs AND Ladders= 2 means of access/ egress within the enclosures w/ safety gates

- Contained Flooring on all levels

Side Baskets- Reduce drops by 90%

Mid Deck (Hydraulic Deck)

- Houses all hydraulic hoses

- Connects to hard piping manifold that allows jumper hoses to connect to quick connects within the control cabin

- 7 Hoses vs 35

- Eliminates unsightly hose bundles=Minimizes trip hazards.

Work Basket

- Engineered with the focus on “Hands Off”

- Minimizing Hand to Iron Contact affected positioning of the tongs and articulating arm

- Tongs on hydraulic controlled track system= No tong pole & spring Stairs- Primary U

- 5 ½ High- torque tongs (m/u & b/o)

- Track system guides tongs over well-center

- Articulating Pipe –Handling Arm- (Hydraulically controlled, meets pipe in v-door and centers pipe over well)

- Safer & more efficient trip times

- Operator works from climate controlled console in the work basket.

Gin Pole

- Rated for 14k lbs. single line pull main winch

- Pins to base

- Telescoping by means of hydraulic cylinders

- Can be pinned after side baskets, before side baskets, or at any other point, vs only being able to stab after rig up is complete.

- Fully operational Crane Smart Box System (main winch)

- 2 heavy duty counterbalance winches

- 55ft cleared height to work basket v-door

- Main winch= Certified Man Rider

Rotary

- Rated for 25K ft. lbs. @ 80 rpm

- On guided track system

Mud Tank

- Complete with Gas Buster rated for 10 bbl. Per minute

- 150 bbl.

- Walkway on side w/ safety gates

- Pason PVT

Mud Pump

- 10M Triplex Pump

- CAT C-15 Zone Rated Class 1, Div. 2, Tier 3 Engine

What Else?

- NORM Meter- Certified NORM Surveyor’s

- Chart Recorders- Own

- 13 5/8 5k Annular

- 13 5/8 10k Pipe/Blind Shear Rams

- Electrical Distribution Panel- All Explosion Proof and Zone Rated

- Hose Baskets, Cargo Baskets- Own

- Fuel Tank, Air Compressor, Electric Generator

- Fuel Tank, Air Compressor, Electric Generator

Life Simplified

- Trucking/ Transport handled by AWI

- Customer sees one price- Rentals, Trucking, BOP Redress, etc., all included in price

- IADC Reporting

- IADC Reporting

Other Safety Factors

- Safety signs within the work platforms

- Non-skid tape within work platformsC

- Diamond Plate throughout

- Fresh water eyewash stations on Mud Tank, Side Baskets; Safety shower in Work Basket

I. Personnel included in 24-hour operation | |

|---|---|

| The following personnel/positions are included in 24-hour operating rate: | |

| Supervisor | 2 |

| Operators | 2 |

| Assistant Operators | 2 |

| Floorman/ Pump Operators | 4 |

| Roustabouts | 2 |

Total Manning Level | 12 |

II. Equipment included in 24-hour operation: | |

|---|---|

The following equipment is included in 24-hour operating rate: | |

| HWO 340K 15 ft. Stroke Jack | 1 |

| HWO Work Basket with Automated Stabbing Arm & Tong Track System | 1 |

| Heavy Duty Gin Pole 14,000 lbs single line pull(main winch) | 1 |

| Heavy Duty Counter Balance Winch Package | 2 |

| Hydraulic Power Pack Powered by CAT C-15 Class 1 Div 2 Tier 3 Engine | 2 |

| 1,000 Gallon DOT Fuel Tank | 1 |

| 12 BBL. Trip Tank | 1 |

| Rotary rated for 25,000 FT LBS @ 80 RPM ( Guided Track System ) | 1 |

| Internal Anti Fall Protection Ladders and stairs with SRL's | 2 |

| 10M Circulating Swivel | 1 |

| 340K HYD Slip Bowls | 3 |

| DNV Tool House Complete with Hand Tools and Spares | 1 |

| LED Lights for HWO Unit Class 1 Div 2 Rated | 8 |

| 10M Well Service Pump Powered by CAT C-15 Class 1 Div 2 Tier 3 Engine | 1 |

| 150 Barrel Tank with variable speed hydraulic agaitators | 1 |

| Gas Buster rated for 10bbl per min | 1 |

| Single Pin Chart Recorder | 1 |

| Sections of High Pressure Hoses (for rig-up) 10M Rated | 2 |

| Suction Hoses (for rig-up) | 6 |

| Dual Air Test Pump | 1 |

| Hydraulic Tubing/Pipe Tongs 25,000 ft. lbs. rated (each set includes backups) | 2 |

| 10M Squeeze Manifold | 1 |

| 13 5/8'' 10M Single LBT Dressed with SBR Shear Rams | 1 |

| 13 5/8'' Annular 5M top 10M Bottom | 1 |

| 13 5/8'' 10M Single Ram BOP Dressed with Flex rams 2 3/8'' x 3 1/2'' | 1 |

| 13 5/8'' 10M Single Ram BOP Dressed with Flex rams 2 3/8'' x 3 1/2'' | 1 |

| 10M Choke and Kill Manual and HCR valves | 1 |

| 10M Dual Hydraulic/Adjustable Choke Manifold | 1 |

| 3" Fluid Transfer Pumps | 2 |

| 250KW Generator | 1 |

| 500 CFM Air Compressor Class 1 Div 2 Rated | 1 |

| 230 Gallon BOP Closing Unit (includes dual remote panels,hoses, alarms 16D) | 1 |

| Communication Package(radios) | 12 |

| EMS PVT System with electronic IADC reporting | 1 |

| Deck Stand lights with LED Lights Class 1 Div 2 Rated | 3 |

| 3'' Over board pumps with Electrical Panel Class 1 Div 2 Rated | 2 |

| Norm Meter | 1 |

| Trucking for our company Related Equipment Only to Customers Dock Location | 10 |

| Transformer Panel Class 1 Div 2 Rated | 1 |

| Trucking for our company Related Equipment Only from Customers Dock Location | 10 |